TS EN 50288-7 Isgaarsiinta & fiilada koontaroolka PVC CAT Analogue Nidaamyada Xakamaynta Isgaarsiinta Dijital ah gudbinta korantada

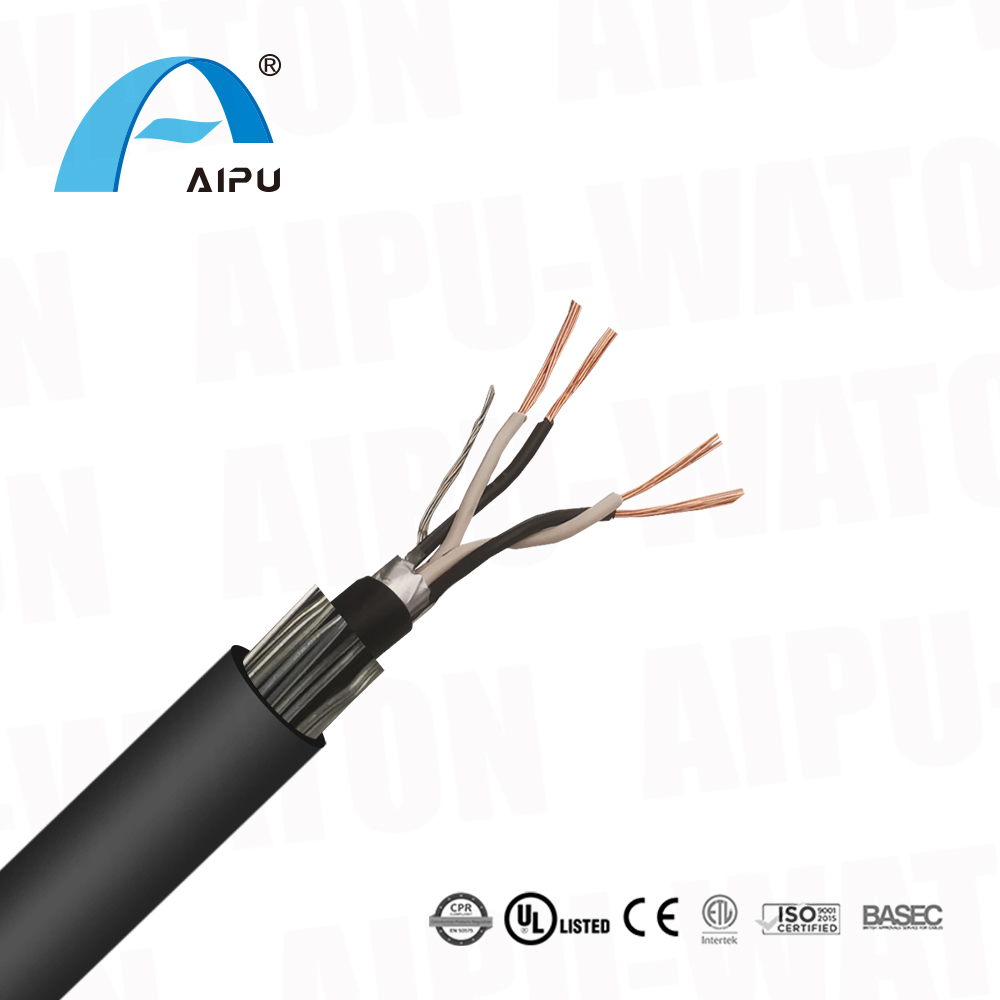

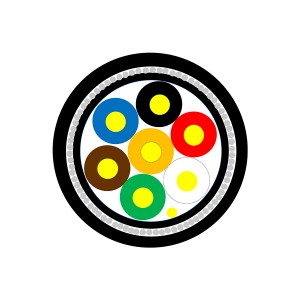

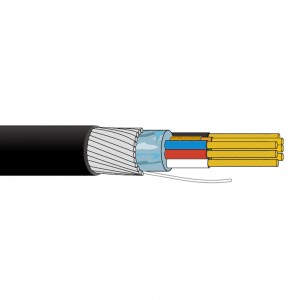

Dhismayaasha

Maamulaha: 0.5 - 0.75:

Heerka 5 daawadeen naxaas ah oo dabacsan

1mm & ka sareeya:

Darajiyaha naxaasta ah ee darajada 2-aad

Dahaarka: Iskutallaabta Polyethylene (XLPE) La dejiyay si uu u sameeyo lammaane

Shaashadda: Shaashadda cajaladaha aluminium/mylar-ga ah oo leh silig naxaas ah oo qasacadaysan

Galka: Polyvinyl Chloride (PVC)

Midabka Galka: Buluug ama Madow

Muddada ugu badan ee hawlgalka waa 15 sano

Heerkulka Rakibaadda: Ka sarreeya 0 ℃

Heerkulka shaqada: -15 ℃ ~ 65 ℃

Voltage lagu qiimeeyay: 90V, 300V, 500V

Tijaabi Voltage (DC): 2000V Inta u dhaxaysa Conductors

2000V inta u dhaxaysa maamule kasta iyo hub

Heerarka Tixraaca

TS EN 50288-7

TS EN 50288-1

TS EN/IEC 60332-3-24

HD383

Dab-demiska BS EN/IEC 60332-1-2

Min. Dhumucda dahaarka

| Cabbirka maamulaha (mm2) | Mini Dhumucda (mm) | |||||

| Voltage lagu qiimeeyay | ||||||

| 90V | Xoogga Dielectric | 300V | Xoogga Dielectric | 500V | Xoogga Dielectric | |

| 0.5 | 0.2 | ≥0.75KVac ama ≥1.5KVdc | 0.26 | ≥1.0KVac ama ≥2.0KVdc | 0.44 | ≥2.0KVac ama ≥3.0KVdc |

| 0.75 | 0.2 | 0.26 | 0.44 | |||

| 1.0 | 0.26 | 0.26 | 0.44 | |||

| 1.5 | 0.3 | 0.35 | 0.44 | |||

Tilmaamaha Guud

| Cabbirka maamulaha (mm2) | Heerka maamulaha | Max. DCR (Ω/km) | Max. Qiimaha Awooda Labada Dhinac pF/m | Max. Isku-dheellitir la'aanta Awoodda lammaanaha/Quads Polyolefin (pF/500m) | Qiyaasta ugu badan ee L/R (μH/Ω) | |

| Polyolefin (nf/km) | PVC (nf/km) | |||||

| 0.5 | 5 | 39.7 | 150 | 250 | 500 | 25 |

| 0.75 | 5 | 26.5 | 150 | 250 | 500 | 25 |

| 1.0 | 5 | 19.8 | 150 | 250 | 500 | 25 |

| 1.5 | 2 | 13.5 | 150 | 250 | 500 | 40 |

90V, Laba-labo badan, PE Insulated, Guud ahaan la baadhay

| Tirada Lamaanaha | Maamule | Dhumucda dahaarka (mm) | La baadhay | Dhumucda galka (mm) | Dhexroorka Guud (mm) | |

| Cabbirka (mm2) | Fasalka | |||||

| 1 | 0.5 | 2,5 | 0.35 | Al-foil | 0.6 | 4.5 |

| 2 | 0.5 | 2,5 | 0.35 | Al-foil | 0.7 | 6.9 |

| 3 | 0.5 | 2,5 | 0.35 | Al-foil | 0.7 | 7.5 |

| 4 | 0.5 | 2,5 | 0.35 | Al-foil | 0.8 | 8.3 |

| 5 | 0.5 | 2,5 | 0.35 | Al-foil | 0.8 | 9.1 |

| 6 | 0.5 | 2,5 | 0.35 | Al-foil | 0.9 | 10.1 |

| 8 | 0.5 | 2,5 | 0.35 | Al-foil | 1 | 11.5 |

| 10 | 0.5 | 2,5 | 0.35 | Al-foil | 1.1 | 13.2 |

| 1 | 0.5 | 2,5 | 0.35 | Al-foil + TC Braided | 0.7 | 5.3 |

| 2 | 0.5 | 2,5 | 0.35 | Al-foil + TC Braided | 0.8 | 7.8 |

| 3 | 0.5 | 2,5 | 0.35 | Al-foil + TC Braided | 0.8 | 8.3 |

| 4 | 0.5 | 2,5 | 0.35 | Al-foil + TC Braided | 0.9 | 9.3 |

| 5 | 0.5 | 2,5 | 0.35 | Al-foil + TC Braided | 0.9 | 10 |

| 6 | 0.5 | 2,5 | 0.35 | Al-foil + TC Braided | 1 | 11.1 |

| 8 | 0.5 | 2,5 | 0.35 | Al-foil + TC Braided | 1 | 12.3 |

| 10 | 0.5 | 2,5 | 0.35 | Al-foil + TC Braided | 1.1 | 14 |

| 1 | 0.75 | 2,5 | 0.35 | Al-foil | 0.6 | 4.9 |

| 2 | 0.75 | 2,5 | 0.35 | Al-foil | 0.7 | 7.6 |

| 3 | 0.75 | 2,5 | 0.35 | Al-foil | 0.7 | 8.2 |

| 4 | 0.75 | 2,5 | 0.35 | Al-foil | 0.8 | 9.1 |

| 5 | 0.75 | 2,5 | 0.35 | Al-foil | 0.9 | 10.2 |

| 6 | 0.75 | 2,5 | 0.35 | Al-foil | 1 | 11.3 |

| 8 | 0.75 | 2,5 | 0.35 | Al-foil | 1.1 | 12.4 |

| 10 | 0.75 | 2,5 | 0.35 | Al-foil | 1.2 | 14.8 |

| 1 | 0.75 | 2,5 | 0.35 | Al-foil + TC Braided | 0.7 | 5.7 |

| 2 | 0.75 | 2,5 | 0.35 | Al-foil + TC Braided | 0.8 | 8.4 |

| 3 | 0.75 | 2,5 | 0.35 | Al-foil + TC Braided | 0.9 | 9.4 |

| 4 | 0.75 | 2,5 | 0.35 | Al-foil + TC Braided | 0.9 | 10.1 |

| 5 | 0.75 | 2,5 | 0.35 | Al-foil + TC Braided | 1 | 11.2 |

| 6 | 0.75 | 2,5 | 0.35 | Al-foil + TC Braided | 1 | 12.1 |

| 8 | 0.75 | 2,5 | 0.35 | Al-foil + TC Braided | 1.1 | 13.7 |

| 10 | 0.75 | 2,5 | 0.35 | Al-foil + TC Braided | 1.2 | 15.5 |

| 1 | 1 | 2,5 | 0.4 | Al-foil | 0.6 | 5.5 |

| 2 | 1 | 2,5 | 0.4 | Al-foil | 0.8 | 8.9 |

| 3 | 1 | 2,5 | 0.4 | Al-foil | 0.9 | 9.8 |

| 4 | 1 | 2,5 | 0.4 | Al-foil | 1 | 10.7 |

| 5 | 1 | 2,5 | 0.4 | Al-foil | 1 | 11.7 |

| 6 | 1 | 2,5 | 0.4 | Al-foil | 1.1 | 13 |

| 8 | 1 | 2,5 | 0.4 | Al-foil | 1.2 | 14.8 |

| 10 | 1 | 2,5 | 0.4 | Al-foil | 1.3 | 17 |

| 1 | 1 | 2,5 | 0.4 | Al-foil + TC Braided | 0.8 | 6.5 |

| 2 | 1 | 2,5 | 0.4 | Al-foil + TC Braided | 0.9 | 9.8 |

| 3 | 1 | 2,5 | 0.4 | Al-foil + TC Braided | 0.9 | 10.6 |

| 4 | 1 | 2,5 | 0.4 | Al-foil + TC Braided | 1 | 11.5 |

| 5 | 1 | 2,5 | 0.4 | Al-foil + TC Braided | 1.1 | 12.7 |

| 6 | 1 | 2,5 | 0.4 | Al-foil + TC Braided | 1.2 | 14 |

| 8 | 1 | 2,5 | 0.4 | Al-foil + TC Braided | 1.3 | 15.8 |

| 10 | 1 | 2,5 | 0.4 | Al-foil + TC Braided | 1.3 | 17.8 |

| 1 | 1.5 | 2,5 | 0.45 | Al-foil | 0.7 | 6.5 |

| 2 | 1.5 | 2,5 | 0.45 | Al-foil | 0.9 | 10.4 |

| 3 | 1.5 | 2,5 | 0.45 | Al-foil | 1 | 11.5 |

| 4 | 1.5 | 2,5 | 0.45 | Al-foil | 1 | 12.4 |

| 5 | 1.5 | 2,5 | 0.45 | Al-foil | 1.1 | 13.8 |

| 6 | 1.5 | 2,5 | 0.45 | Al-foil | 1.2 | 15.3 |

| 8 | 1.5 | 2,5 | 0.45 | Al-foil | 1.3 | 17.4 |

| 10 | 1.5 | 2,5 | 0.45 | Al-foil | 1.4 | 19.9 |

| 1 | 1.5 | 2,5 | 0.45 | Al-foil + TC Braided | 0.8 | 7.3 |

| 2 | 1.5 | 2,5 | 0.45 | Al-foil + TC Braided | 1 | 11.4 |

| 3 | 1.5 | 2,5 | 0.45 | Al-foil + TC Braided | 1 | 12.3 |

| 4 | 1.5 | 2,5 | 0.45 | Al-foil + TC Braided | 1.1 | 13.4 |

| 5 | 1.5 | 2,5 | 0.45 | Al-foil + TC Braided | 1.2 | 14.8 |

| 6 | 1.5 | 2,5 | 0.45 | Al-foil + TC Braided | 1.3 | 16.3 |

| 8 | 1.5 | 2,5 | 0.45 | Al-foil + TC Braided | 1.4 | 18.4 |

| 10 | 1.5 | 2,5 | 0.45 | Al-foil + TC Braided | 1.4 | 20.7 |

300V, Laba-labo badan, PE Insulated, Guud ahaan la baadhay

| Tirada Lamaanaha | Maamule | Dhumucda dahaarka (mm) | La baadhay | Dhumucda galka (mm) | Dhexroorka Guud (mm) | |

| Cabbirka (mm2) | Fasalka | |||||

| 1 | 0.5 | 2,5 | 0.4 | Al-foil | 0.6 | 4.7 |

| 2 | 0.5 | 2,5 | 0.4 | Al-foil | 0.7 | 7.3 |

| 3 | 0.5 | 2,5 | 0.4 | Al-foil | 0.8 | 8.1 |

| 4 | 0.5 | 2,5 | 0.4 | Al-foil | 0.8 | 8.7 |

| 5 | 0.5 | 2,5 | 0.4 | Al-foil | 0.9 | 9.7 |

| 6 | 0.5 | 2,5 | 0.4 | Al-foil | 1 | 10.8 |

| 8 | 0.5 | 2,5 | 0.4 | Al-foil | 1 | 12.1 |

| 10 | 0.5 | 2,5 | 0.4 | Al-foil | 1.1 | 13.9 |

| 1 | 0.5 | 2,5 | 0.4 | Al-foil + TC Braided | 0.7 | 5.5 |

| 2 | 0.5 | 2,5 | 0.4 | Al-foil + TC Braided | 0.8 | 8.1 |

| 3 | 0.5 | 2,5 | 0.4 | Al-foil + TC Braided | 0.8 | 8.7 |

| 4 | 0.5 | 2,5 | 0.4 | Al-foil + TC Braided | 0.9 | 9.7 |

| 5 | 0.5 | 2,5 | 0.4 | Al-foil + TC Braided | 1 | 10.7 |

| 6 | 0.5 | 2,5 | 0.4 | Al-foil + TC Braided | 1 | 11.6 |

| 8 | 0.5 | 2,5 | 0.4 | Al-foil + TC Braided | 1.1 | 13.1 |

| 10 | 0.5 | 2,5 | 0.4 | Al-foil + TC Braided | 1.2 | 14.9 |

| 1 | 0.75 | 2,5 | 0.4 | Al-foil | 0.6 | 5.3 |

| 2 | 0.75 | 2,5 | 0.4 | Al-foil | 0.7 | 8.3 |

| 3 | 0.75 | 2,5 | 0.4 | Al-foil | 0.8 | 9.2 |

| 4 | 0.75 | 2,5 | 0.4 | Al-foil | 0.9 | 10.1 |

| 5 | 0.75 | 2,5 | 0.4 | Al-foil | 1 | 11.3 |

| 6 | 0.75 | 2,5 | 0.4 | Al-foil | 1 | 12.3 |

| 8 | 0.75 | 2,5 | 0.4 | Al-foil | 1.1 | 14 |

| 10 | 0.75 | 2,5 | 0.4 | Al-foil | 1.2 | 16.1 |

| 1 | 0.75 | 2,5 | 0.4 | Al-foil + TC Braided | 0.8 | 7.5 |

| 2 | 0.75 | 2,5 | 0.4 | Al-foil + TC Braided | 0.8 | 9.3 |

| 3 | 0.75 | 2,5 | 0.4 | Al-foil + TC Braided | 0.9 | 10.2 |

| 4 | 0.75 | 2,5 | 0.4 | Al-foil + TC Braided | 0.9 | 11.1 |

| 5 | 0.75 | 2,5 | 0.4 | Al-foil + TC Braided | 1 | 12.1 |

| 6 | 0.75 | 2,5 | 0.4 | Al-foil + TC Braided | 1.1 | 13.3 |

| 8 | 0.75 | 2,5 | 0.4 | Al-foil + TC Braided | 1.2 | 15 |

| 10 | 0.75 | 2,5 | 0.4 | Al-foil + TC Braided | 1.3 | 17.1 |

| 1 | 1 | 2,5 | 0.4 | Al-foil | 0.6 | 5.5 |

| 2 | 1 | 2,5 | 0.4 | Al-foil | 0.8 | 8.9 |

| 3 | 1 | 2,5 | 0.4 | Al-foil | 0.9 | 9.8 |

| 4 | 1 | 2,5 | 0.4 | Al-foil | 1 | 10.7 |

| 5 | 1 | 2,5 | 0.4 | Al-foil | 1 | 11.7 |

| 6 | 1 | 2,5 | 0.4 | Al-foil | 1.1 | 13 |

| 8 | 1 | 2,5 | 0.4 | Al-foil | 1.2 | 14.8 |

| 10 | 1 | 2,5 | 0.4 | Al-foil | 1.3 | 17 |

| 1 | 1 | 2,5 | 0.4 | Al-foil + TC Braided | 0.8 | 6.5 |

| 2 | 1 | 2,5 | 0.4 | Al-foil + TC Braided | 0.9 | 9.8 |

| 3 | 1 | 2,5 | 0.4 | Al-foil + TC Braided | 0.9 | 10.6 |

| 4 | 1 | 2,5 | 0.4 | Al-foil + TC Braided | 1 | 11.5 |

| 5 | 1 | 2,5 | 0.4 | Al-foil + TC Braided | 1.1 | 12.7 |

| 6 | 1 | 2,5 | 0.4 | Al-foil + TC Braided | 1.2 | 14 |

| 8 | 1 | 2,5 | 0.4 | Al-foil + TC Braided | 1.3 | 15.8 |

| 10 | 1 | 2,5 | 0.4 | Al-foil + TC Braided | 1.3 | 17.8 |

| 1 | 1.5 | 2,5 | 0.5 | Al-foil | 0.7 | 6.7 |

| 2 | 1.5 | 2,5 | 0.5 | Al-foil | 1 | 11 |

| 3 | 1.5 | 2,5 | 0.5 | Al-foil | 1 | 11.8 |

| 4 | 1.5 | 2,5 | 0.5 | Al-foil | 1.1 | 13 |

| 5 | 1.5 | 2,5 | 0.5 | Al-foil | 1.2 | 14.4 |

| 6 | 1.5 | 2,5 | 0.5 | Al-foil | 1.3 | 16 |

| 8 | 1.5 | 2,5 | 0.5 | Al-foil | 1.4 | 18.2 |

| 10 | 1.5 | 2,5 | 0.5 | Al-foil | 1.4 | 20.6 |

| 1 | 1.5 | 2,5 | 0.5 | Al-foil + TC Braided | 0.8 | 7.5 |

| 2 | 1.5 | 2,5 | 0.5 | Al-foil + TC Braided | 1 | 11.8 |

| 3 | 1.5 | 2,5 | 0.5 | Al-foil + TC Braided | 1.1 | 12.8 |

| 4 | 1.5 | 2,5 | 0.5 | Al-foil + TC Braided | 1.2 | 14 |

| 5 | 1.5 | 2,5 | 0.5 | Al-foil + TC Braided | 1.2 | 15.2 |

| 6 | 1.5 | 2,5 | 0.5 | Al-foil + TC Braided | 1.3 | 16.8 |

| 8 | 1.5 | 2,5 | 0.5 | Al-foil + TC Braided | 1.4 | 19 |

| 10 | 1.5 | 2,5 | 0.5 | Al-foil + TC Braided | 1.4 | 21.4 |

500V, Laba-labo badan, PE Insulated, Guud ahaan la baadhay

| Tirada Lamaanaha | Maamule | Dhumucda dahaarka (mm) | La baadhay | Dhumucda galka (mm) | Dhexroorka Guud (mm) | |

| Cabbirka (mm2) | Fasalka | |||||

| 1 | 0.5 | 2,5 | 0.6 | Al-foil | 0.6 | 5.5 |

| 2 | 0.5 | 2,5 | 0.6 | Al-foil | 0.8 | 8.9 |

| 3 | 0.5 | 2,5 | 0.6 | Al-foil | 0.9 | 9.8 |

| 4 | 0.5 | 2,5 | 0.6 | Al-foil | 1 | 10.7 |

| 5 | 0.5 | 2,5 | 0.6 | Al-foil | 1 | 11.7 |

| 6 | 0.5 | 2,5 | 0.6 | Al-foil | 1.1 | 13 |

| 8 | 0.5 | 2,5 | 0.6 | Al-foil | 1.2 | 14.8 |

| 10 | 0.5 | 2,5 | 0.6 | Al-foil | 1.3 | 17 |

| 1 | 0.5 | 2,5 | 0.6 | Al-foil + TC Braided | 0.8 | 6.5 |

| 2 | 0.5 | 2,5 | 0.6 | Al-foil + TC Braided | 0.9 | 9.8 |

| 3 | 0.5 | 2,5 | 0.6 | Al-foil + TC Braided | 0.9 | 10.6 |

| 4 | 0.5 | 2,5 | 0.6 | Al-foil + TC Braided | 1 | 11.5 |

| 5 | 0.5 | 2,5 | 0.6 | Al-foil + TC Braided | 1.1 | 12.7 |

| 6 | 0.5 | 2,5 | 0.6 | Al-foil + TC Braided | 1.2 | 14 |

| 8 | 0.5 | 2,5 | 0.6 | Al-foil + TC Braided | 1.3 | 15.8 |

| 10 | 0.5 | 2,5 | 0.6 | Al-foil + TC Braided | 1.3 | 17.8 |

| 1 | 0.75 | 2,5 | 0.6 | Al-foil | 0.7 | 6.1 |

| 2 | 0.75 | 2,5 | 0.6 | Al-foil | 0.9 | 9.7 |

| 3 | 0.75 | 2,5 | 0.6 | Al-foil | 0.9 | 10.5 |

| 4 | 0.75 | 2,5 | 0.6 | Al-foil | 1 | 11.6 |

| 5 | 0.75 | 2,5 | 0.6 | Al-foil | 1.1 | 12.9 |

| 6 | 0.75 | 2,5 | 0.6 | Al-foil | 1.2 | 14.2 |

| 8 | 0.75 | 2,5 | 0.6 | Al-foil | 1.3 | 16.2 |

| 10 | 0.75 | 2,5 | 0.6 | Al-foil | 1.3 | 18.4 |

| 1 | 0.75 | 2,5 | 0.6 | Al-foil + TC Braided | 0.8 | 6.9 |

| 2 | 0.75 | 2,5 | 0.6 | Al-foil + TC Braided | 1 | 10.7 |

| 3 | 0.75 | 2,5 | 0.6 | Al-foil + TC Braided | 1 | 11.5 |

| 4 | 0.75 | 2,5 | 0.6 | Al-foil + TC Braided | 1 | 12.4 |

| 5 | 0.75 | 2,5 | 0.6 | Al-foil + TC Braided | 1.1 | 13.7 |

| 6 | 0.75 | 2,5 | 0.6 | Al-foil + TC Braided | 1.2 | 15 |

| 8 | 0.75 | 2,5 | 0.6 | Al-foil + TC Braided | 1.3 | 17 |

| 10 | 0.75 | 2,5 | 0.6 | Al-foil + TC Braided | 1.4 | 19.4 |

| 1 | 1 | 2,5 | 0.6 | Al-foil | 0.7 | 6.5 |

| 2 | 1 | 2,5 | 0.6 | Al-foil | 0.9 | 10.4 |

| 3 | 1 | 2,5 | 0.6 | Al-foil | 1 | 11.5 |

| 4 | 1 | 2,5 | 0.6 | Al-foil | 1 | 12.4 |

| 5 | 1 | 2,5 | 0.6 | Al-foil | 1.1 | 13.8 |

| 6 | 1 | 2,5 | 0.6 | Al-foil | 1.2 | 15.3 |

| 8 | 1 | 2,5 | 0.6 | Al-foil | 1.3 | 17.4 |

| 10 | 1 | 2,5 | 0.6 | Al-foil | 1.4 | 19.9 |

| 1 | 1 | 2,5 | 0.6 | Al-foil + TC Braided | 0.8 | 7.3 |

| 2 | 1 | 2,5 | 0.6 | Al-foil + TC Braided | 1 | 11.4 |

| 3 | 1 | 2,5 | 0.6 | Al-foil + TC Braided | 1 | 12.3 |

| 4 | 1 | 2,5 | 0.6 | Al-foil + TC Braided | 1.1 | 13.4 |

| 5 | 1 | 2,5 | 0.6 | Al-foil + TC Braided | 1.2 | 14.8 |

| 6 | 1 | 2,5 | 0.6 | Al-foil + TC Braided | 1.3 | 16.3 |

| 8 | 1 | 2,5 | 0.6 | Al-foil + TC Braided | 1.4 | 18.4 |

| 10 | 1 | 2,5 | 0.6 | Al-foil + TC Braided | 1.4 | 20.7 |

| 1 | 1.5 | 2,5 | 0.6 | Al-foil | 0.8 | 7.3 |

| 2 | 1.5 | 2,5 | 0.6 | Al-foil | 1 | 11.6 |

| 3 | 1.5 | 2,5 | 0.6 | Al-foil | 1 | 12.6 |

| 4 | 1.5 | 2,5 | 0.6 | Al-foil | 1.1 | 13.8 |

| 5 | 1.5 | 2,5 | 0.6 | Al-foil | 1.2 | 15.4 |

| 6 | 1.5 | 2,5 | 0.6 | Al-foil | 1.3 | 17 |

| 8 | 1.5 | 2,5 | 0.6 | Al-foil | 1.4 | 19.3 |

| 10 | 1.5 | 2,5 | 0.6 | Al-foil | 1.4 | 22 |

| 1 | 1.5 | 2,5 | 0.6 | Al-foil + TC Braided | 0.8 | 7.9 |

| 2 | 1.5 | 2,5 | 0.6 | Al-foil + TC Braided | 1 | 12.6 |

| 3 | 1.5 | 2,5 | 0.6 | Al-foil + TC Braided | 1.1 | 13.6 |

| 4 | 1.5 | 2,5 | 0.6 | Al-foil + TC Braided | 1.2 | 14.8 |

| 5 | 1.5 | 2,5 | 0.6 | Al-foil + TC Braided | 1.2 | 16.4 |

| 6 | 1.5 | 2,5 | 0.6 | Al-foil + TC Braided | 1.3 | 17.8 |

| 8 | 1.5 | 2,5 | 0.6 | Al-foil + TC Braided | 1.4 | 20.1 |

| 10 | 1.5 | 2,5 | 0.6 | Al-foil + TC Braided | 1.4 | 22.7 |